Shelter

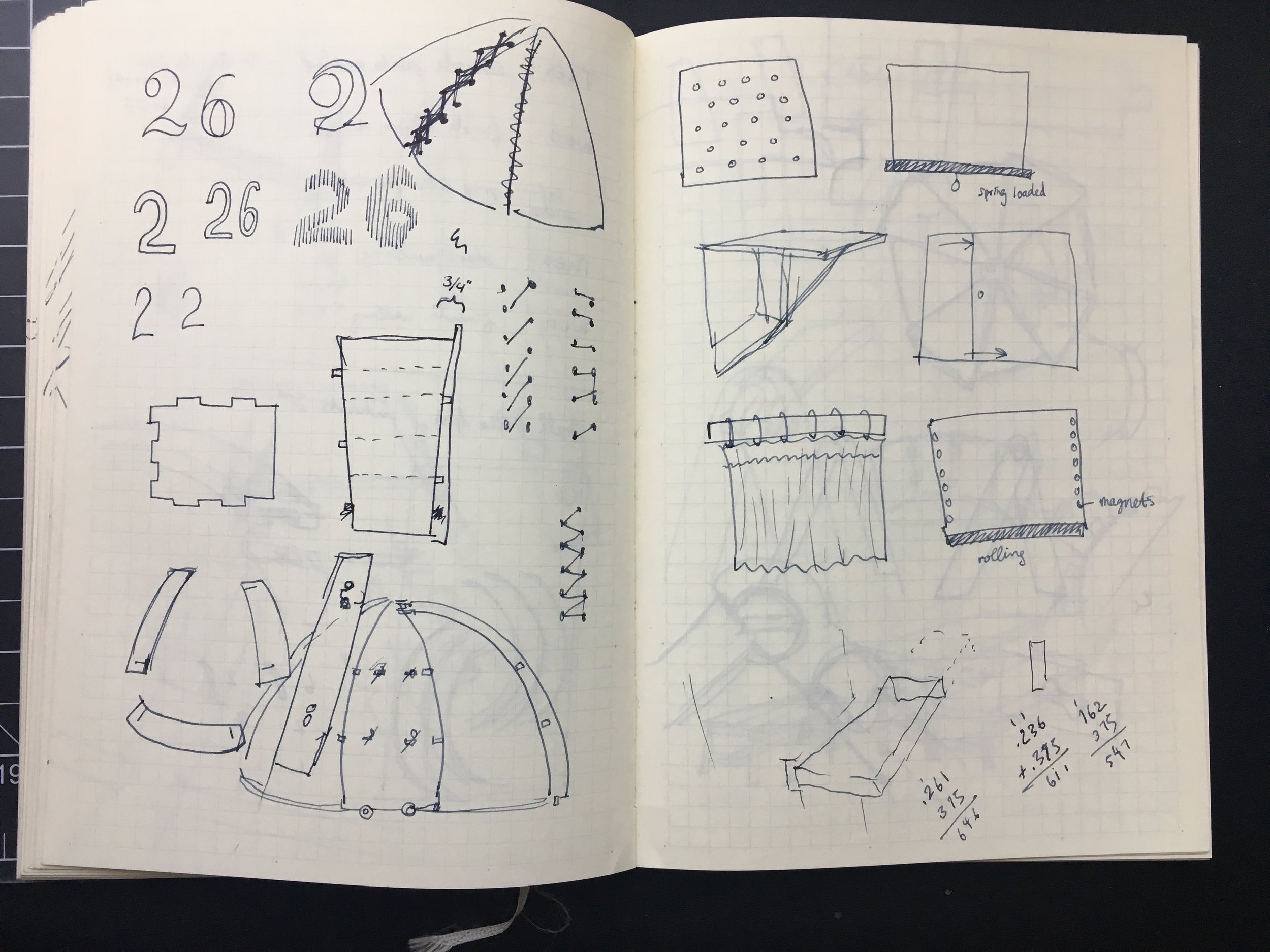

Designing, building, and assembling a shelter without the use of connective materials.

Overview

Contribution

Ideation / 3D Modeling in Rhino / CNC Milling / Soft Goods / Assembly

Team

Alex Bucher, Janice Foo

Use digital fabrication technologies to build a shelter.

Tools

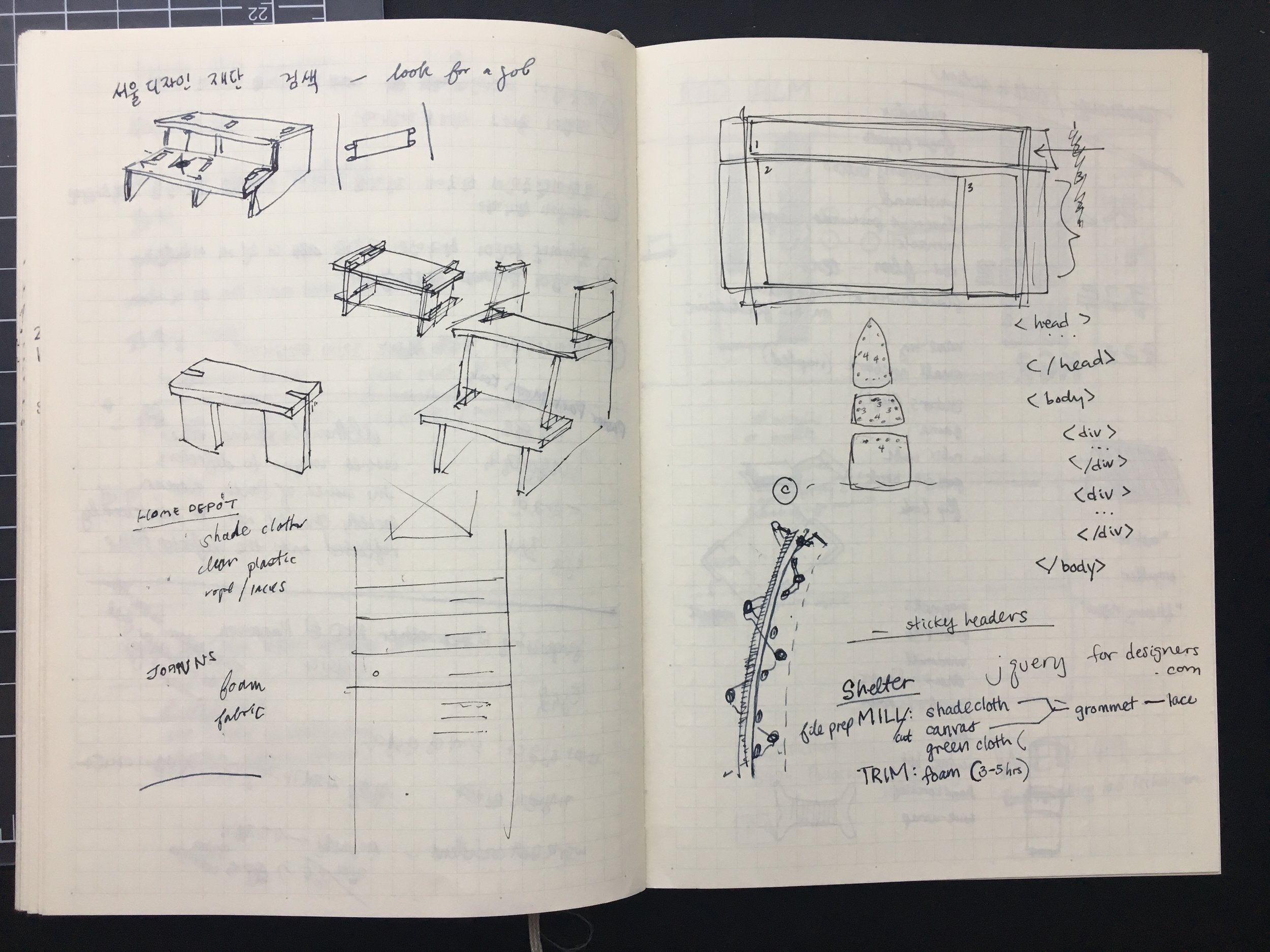

Rhino, CNC mill, and pencil/paper.

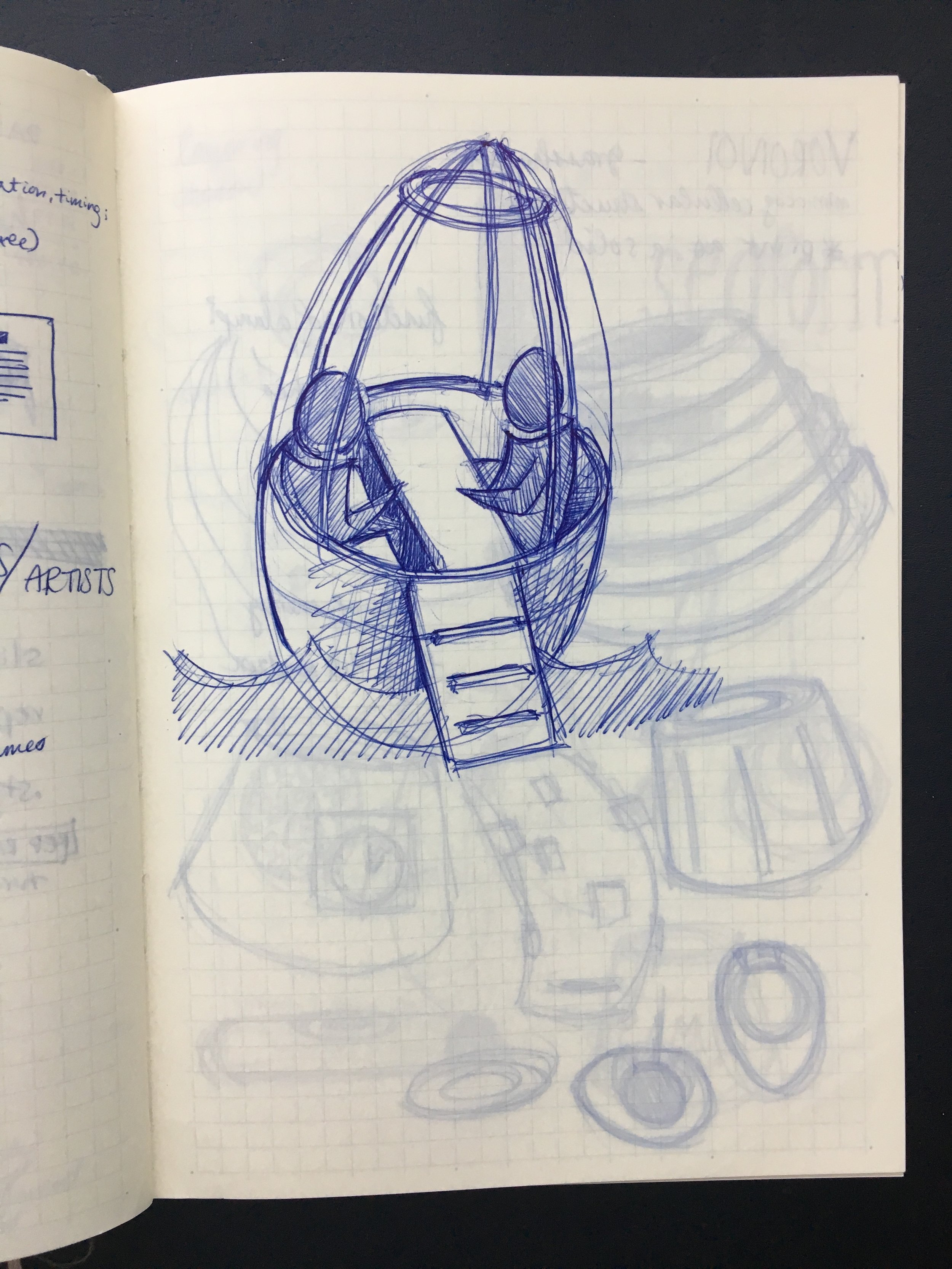

Concept

To be sheltered.

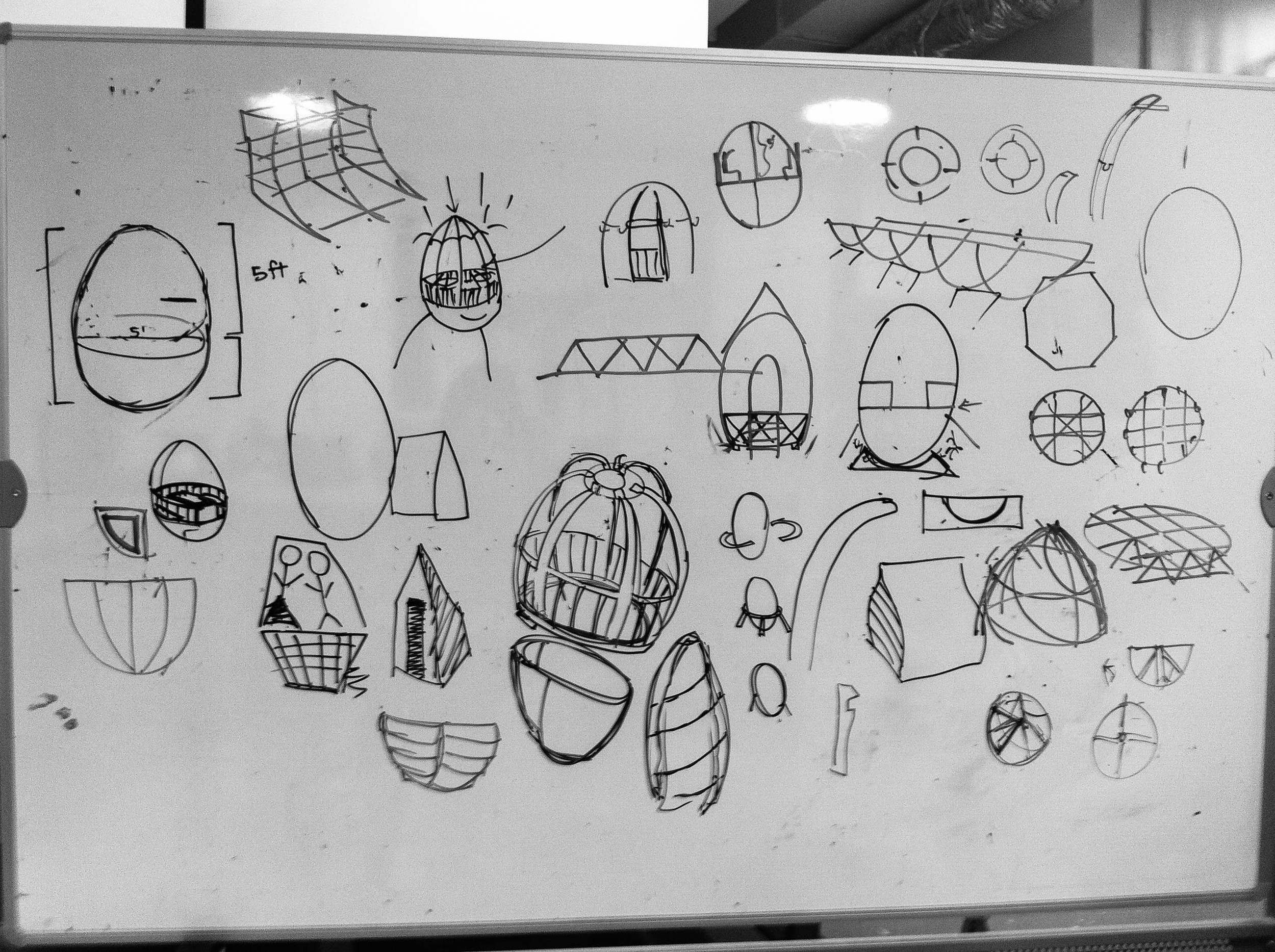

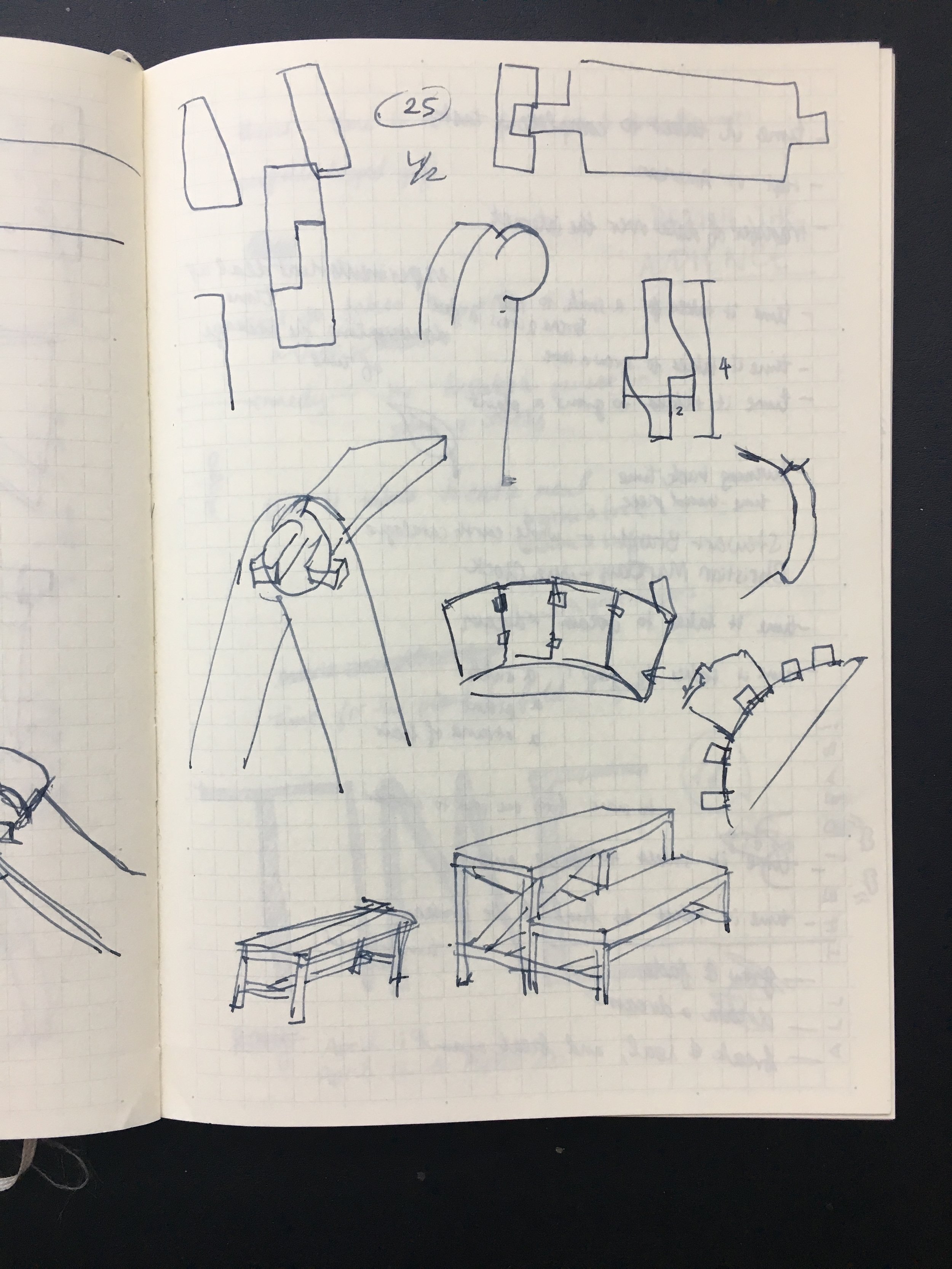

Two key aspects defined the form of the shelter:

- The ability to sit

- The ability to stand

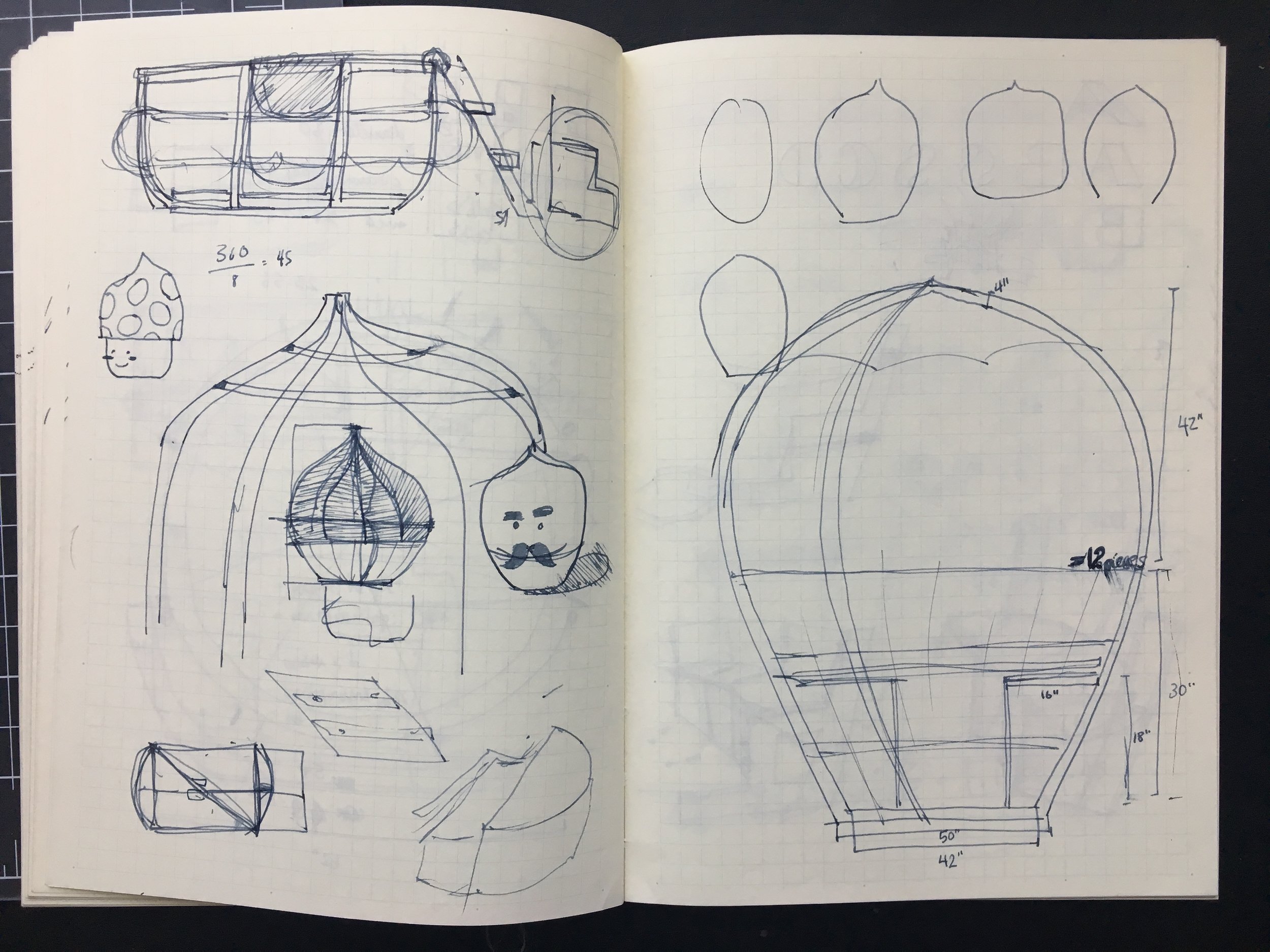

As a first foray into the 3D space, the shelter posed interesting structural challenges. The structure's floor and built-in seats needed to support the weight of four adults. The wide and airy top would provide much-needed breathing room in rather a confined area.

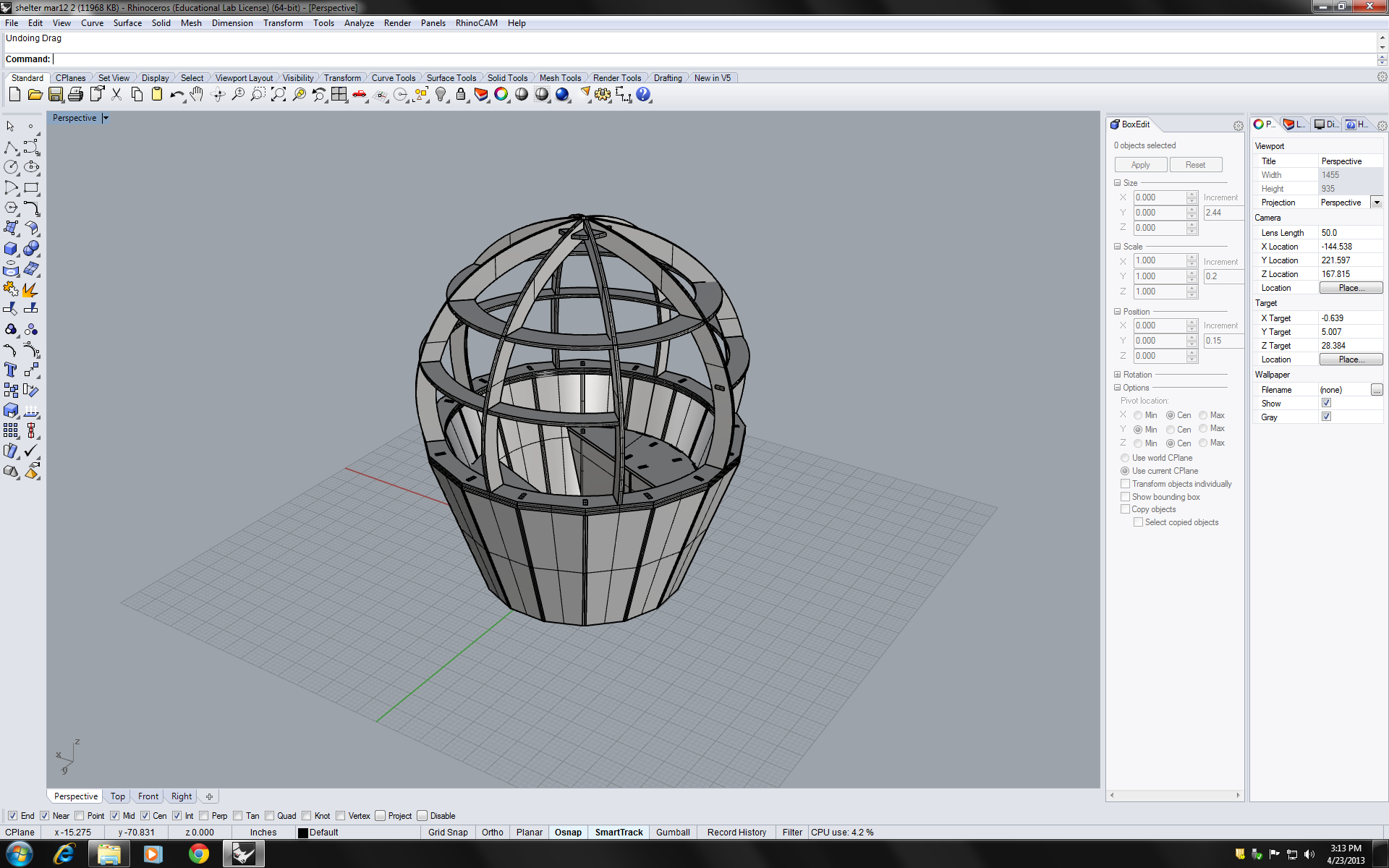

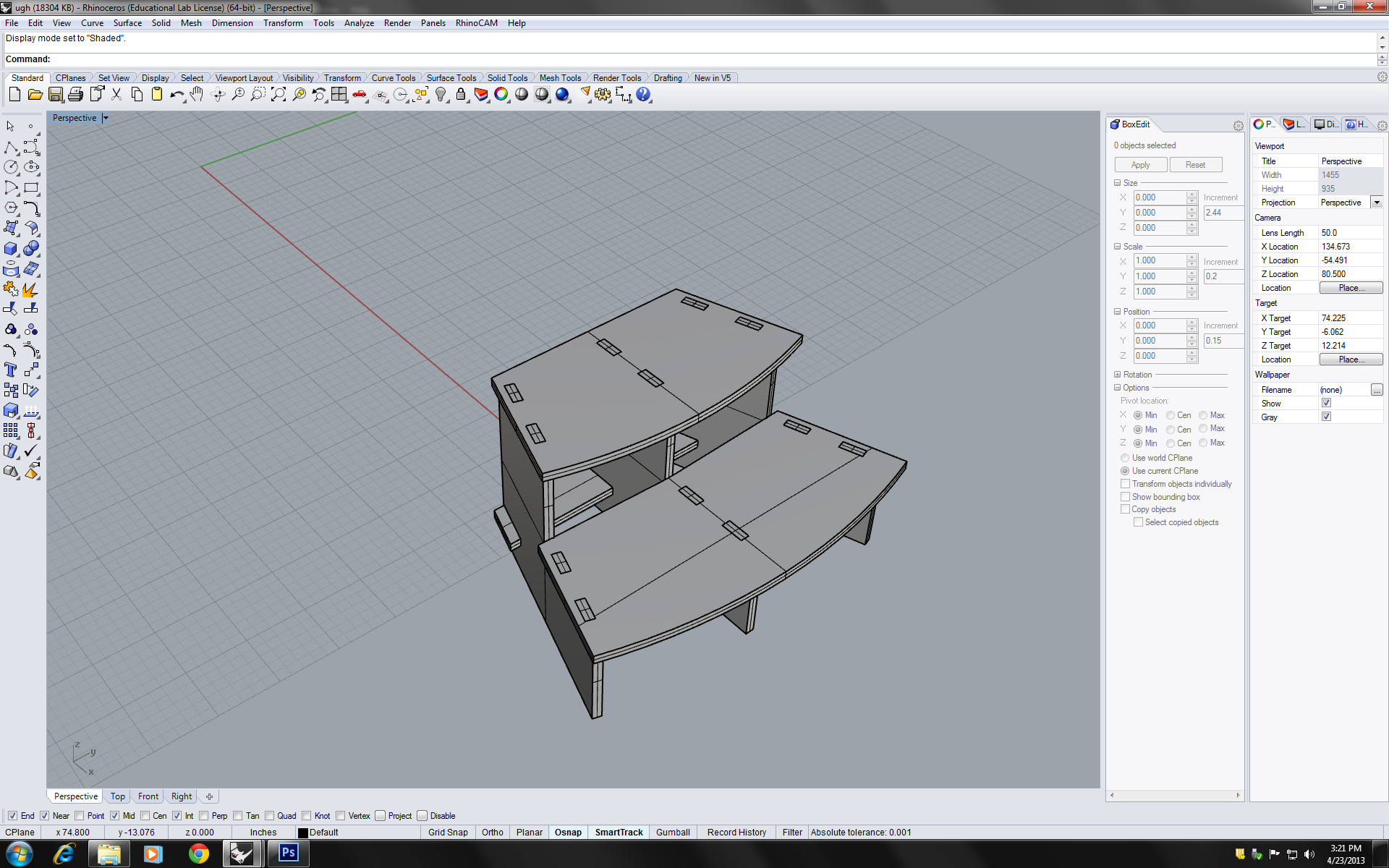

Modeling

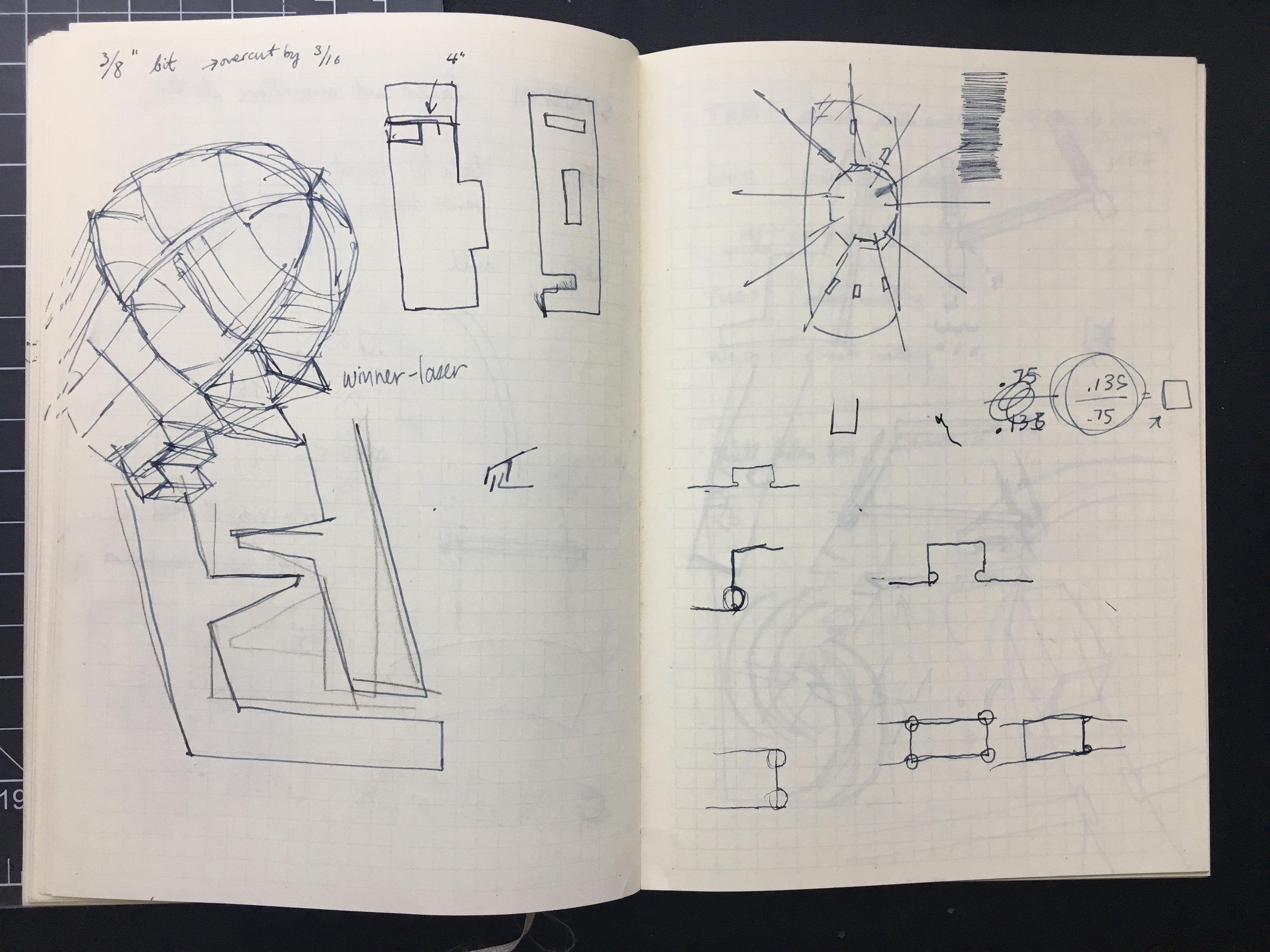

Each team member took turns building out the pieces of the shelter in Rhino. The design was constructed according to specifications we had sketched out. The walls of the structure were built to be tall and withstand potential flooding. We also designed a step stool for easy access into the shelter.

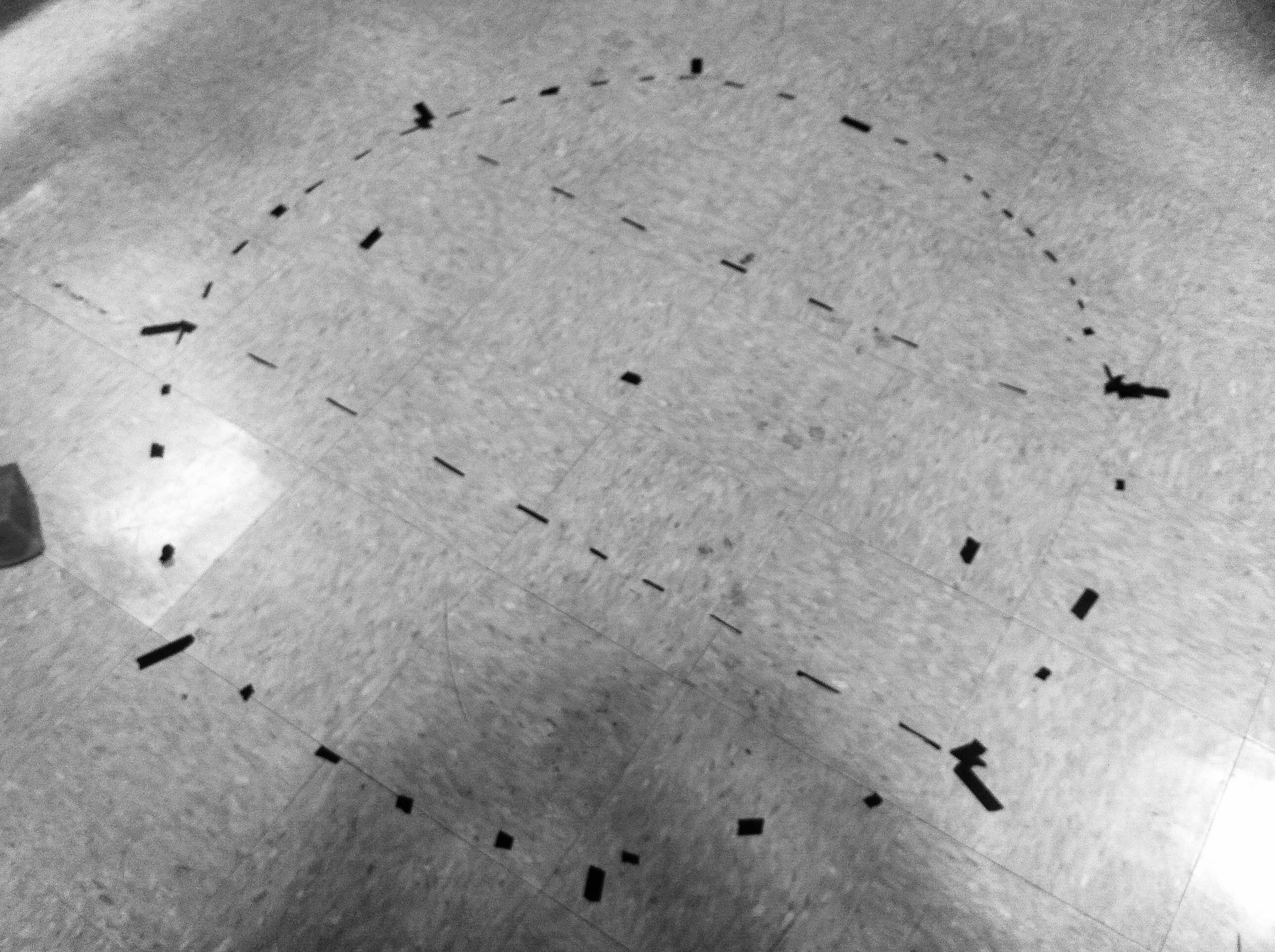

After carefully making sure each joint would be a perfect friction fit, we laid out the pieces to save as much material as possible during the milling.

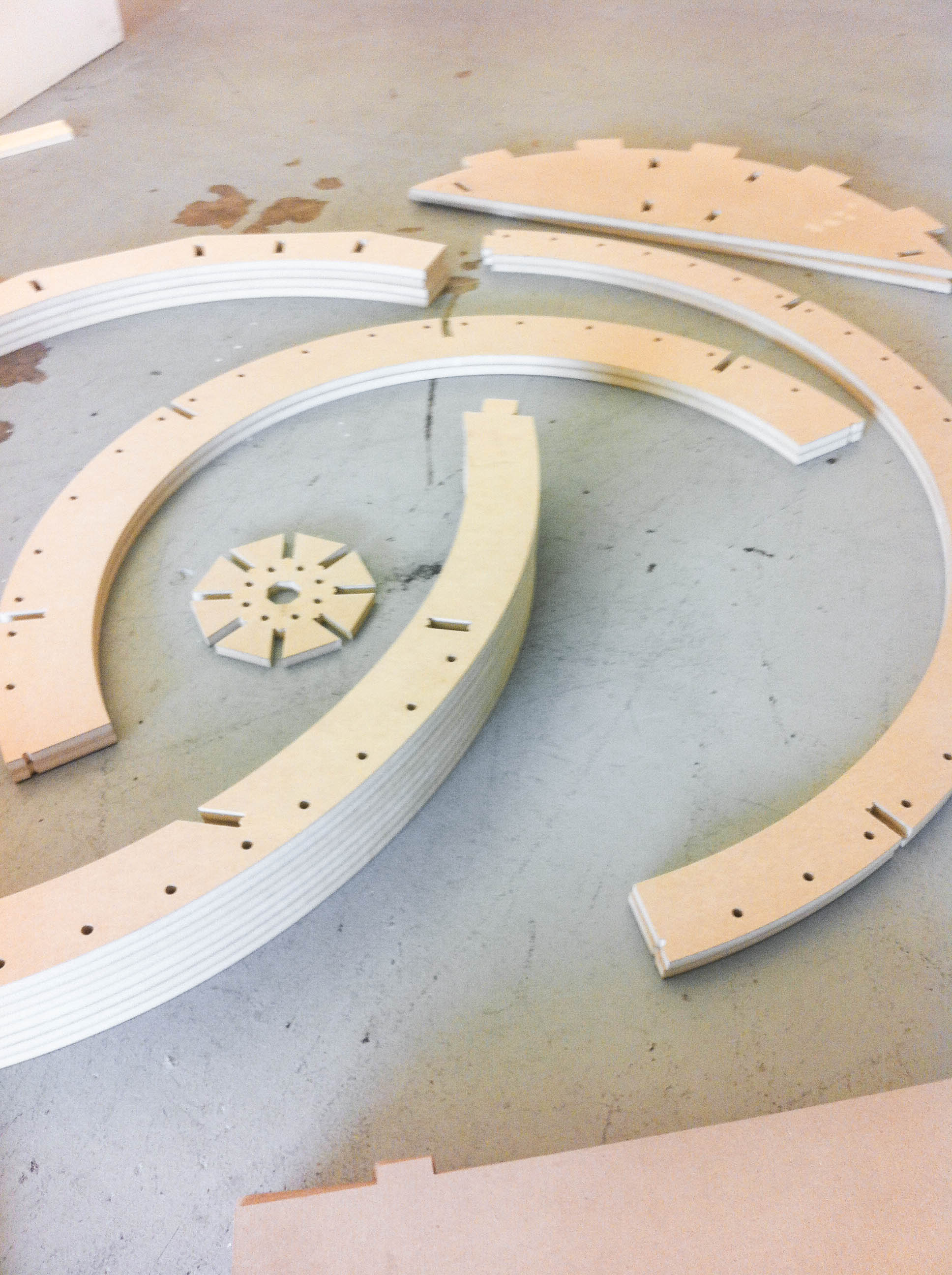

Assembly

The to-scale prototype was built out of MDF-- unsustainable material for an actual shelter, but suitable for our proof-of-concept. Grommeted pieces of shade sail provided cover, with a design for an additional layer of waxed canvas. We used twine, clothesline, and buttons lashed together to create window flaps that could be tied down.

Our structure was essentially a series of interlocking parts completed the assembly of the structure, with each piece fitting perfectly in accordance with the angles we had designed in Rhino.

The final shelter fit six full-grown adults with relative ease and was on display at the Washington D.C. Fab Lab for the summer of 2013.